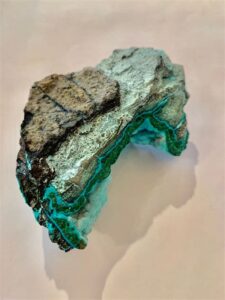

Known for its captivating banded patterns and vibrant colors, agate ranks among the most popular gemstones. Its durability, measured by hardness, plays a crucial role in determining its suitability for various applications, from jewelry and decorative pieces to industrial tools.

Hardness Scale of Agate

Agate falls within the range of 6.5 to 7.0 on the Mohs scale of mineral hardness. This scale, developed by German geologist Friedrich Mohs in 1822, assigns hardness values based on the ability of one mineral to scratch another.

Understanding Agate’s Hardness

- 6.5 on Mohs Scale: This is the lower end of agate’s hardness range, indicating that it can be scratched by materials such as steel and glass.

- 7.0 on Mohs Scale: The upper end of the range signifies that agate is harder than glass but softer than quartz (hardness of 7).

Impact of Hardness on Applications

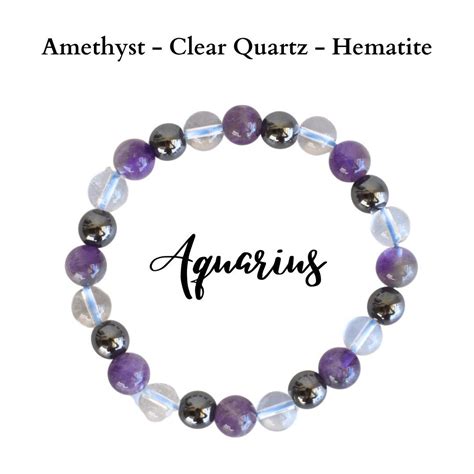

- Jewelry: Agate’s moderate hardness makes it suitable for crafting earrings, necklaces, and bracelets. It is durable enough to withstand everyday wear and tear, yet soft enough to be easily shaped and polished.

- Decorative Objects: Agate’s hardness allows it to be used in decorative items such as sculptures, paperweights, and coasters. It can be carved or polished to create intricate designs and patterns.

- Industrial Uses: Agate’s toughness makes it a viable material for certain industrial applications. It is used in grinding and polishing tools, as well as in the production of mortar and pestles.

Factors Affecting Hardness

- Microcrystalline Structure: Agate consists of microscopic quartz crystals that are tightly interlocked. This microcrystalline structure contributes to its hardness.

- Crystal Orientation: The orientation of the individual crystals within the agate influences its overall hardness.

- Chemical Composition: Minor variations in the chemical composition of agate can affect its hardness. Impurities like iron or manganese can slightly alter the crystal structure and therefore the stone’s hardness.

Onychocryptosis: A New Concept

The term “onychocryptosis” has been coined to describe the phenomenon of agate’s resistance to scratching or deformation. This concept highlights the exceptional durability of the stone, making it an ideal choice for applications where resistance to wear and damage is paramount.

Tables

Table 1: Comparison of Agate Hardness to Other Minerals

| Mineral | Mohs Hardness |

|---|---|

| Agate | 6.5-7.0 |

| Glass | 5.5 |

| Steel | 7.5 |

| Quartz | 7.0 |

Table 2: Applications of Agate Based on Hardness

| Application | Hardness Range |

|---|---|

| Jewelry | 6.5-7.0 |

| Decorative Objects | 6.5-7.0 |

| Grinding Tools | 6.5-7.0 |

| Mortar and Pestles | 6.5-7.0 |

Table 3: Factors Affecting Agate Hardness

| Factor | Description |

|---|---|

| Microcrystalline Structure | Tightly interlocked microscopic quartz crystals |

| Crystal Orientation | Arrangement of individual crystals within the agate |

| Chemical Composition | Minor variations in the presence of impurities |

Table 4: Hardness Ranges for Different Agate Varieties

| Variety | Mohs Hardness |

|---|---|

| Chalcedony | 6.5-7.0 |

| Onyx | 6.5-7.0 |

| Sardonyx | 6.5-7.0 |

| Heliotrope | 6.5-7.0 |

| Moss Agate | 6.5-7.0 |

Case Study: Using Agate in Industrial Applications

In the automotive industry, agate is utilized in grinding wheels for polishing metal parts. Its hardness and durability enable it to withstand the rigorous wear and tear associated with this process.

Conclusion

Agate’s hardness plays a significant role in determining its versatility and suitability for a wide range of applications. Its moderate hardness makes it strong enough for everyday use while allowing for intricate carving and shaping. Understanding the factors that affect agate’s hardness empowers users to select the appropriate variety for their specific needs. As research continues to explore its potential, new applications for this enduring stone are likely to emerge.