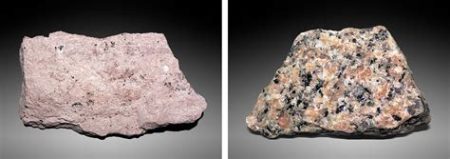

Orthogneiss, an enigmatic rock formation, captivates geologists and explorers alike with its captivating juxtaposition of black and white. This guide delves into the fascinating world of orthogneiss, illuminating its formation, composition, and intriguing applications.

Genesis of Orthogneiss: Magma’s Metamorphic Odyssey

Orthogneiss originates from igneous rocks, primarily granite, that undergo intense heat and pressure within the Earth’s crust. This metamorphic process, driven by tectonic forces, transforms the original igneous minerals into new minerals, giving orthogneiss its distinct banded appearance. The dark bands are typically rich in mafic minerals such as biotite and hornblende, while the lighter bands are composed of felsic minerals like quartz and feldspar.

Chemical Composition: A Rock’s Fingerprint

The chemical composition of orthogneiss reflects its igneous heritage. It is typically composed of approximately 60-75% silica (SiO2), 10-15% aluminum oxide (Al2O3), and smaller proportions of other elements such as potassium oxide (K2O), sodium oxide (Na2O), calcium oxide (CaO), magnesium oxide (MgO), and iron oxide (FeO).

Occurrence and Distribution: A Global Geological Tapestry

Orthogneiss occurs worldwide, with notable exposures found in Precambrian shields, such as the Canadian Shield and the Baltic Shield. It is also commonly found in mountain belts and other areas that have experienced significant tectonic activity.

Engineering Properties: Strength and Versatility

Orthogneiss exhibits exceptional engineering properties, making it a valuable material for construction and landscaping applications. Its high compressive strength, ranging from 100 to 250 MPa, and its resistance to weathering and abrasion make it a durable and reliable building material.

Applications: From Buildings to Monuments

Orthogneiss has a wide range of applications, including:

- Construction: Foundations, walls, paving stones, and decorative elements

- Landscaping: Retaining walls, garden paths, and rock gardens

- Monuments: Statues, memorials, and historical markers

Orthogneiss in the Spotlight: A Case Study

The iconic Aswan Dam in Egypt is a testament to the remarkable strength and durability of orthogneiss. The dam’s construction utilized approximately 36 million cubic meters of orthogneiss quarried from nearby quarries. Despite being exposed to extreme heat, water, and geological forces for over a century, the orthogneiss blocks remain intact, a testament to the rock’s exceptional engineering properties.

Common Pitfalls to Avoid: Enhancing Project Success

To achieve optimal results when working with orthogneiss, it is essential to avoid common mistakes, such as:

- Improper Handling: Mishandling orthogneiss can lead to breakage or damage. Use proper lifting equipment and follow manufacturer’s guidelines.

- Exposure to Harsh Environments: Extended exposure to extreme temperatures, moisture, or corrosive agents can compromise the rock’s integrity. Utilize protective coatings or treatments to minimize degradation.

- Insufficient Curing Time: Allow sufficient curing time for mortars or adhesives used with orthogneiss to ensure proper bonding and strength development.

Comparative Analysis: Orthogneiss vs. Other Rocks

When selecting a rock for a specific application, it is crucial to compare its properties to those of other potential materials. Here is a comparative analysis of orthogneiss against two common alternatives:

| Property | Orthogneiss | Granite | Limestone |

|---|---|---|---|

| Compressive Strength (MPa) | 100-250 | 100-200 | 25-250 |

| Density (kg/m³) | 2650-2800 | 2600-2750 | 2400-2700 |

| Water Absorption (%) | 0.2-0.5 | 0.2-0.5 | 3-10 |

| Frost Resistance | Moderate | High | Low |

Innovation in Orthogneiss Applications: The Future is Bright

Researchers are exploring innovative applications for orthogneiss, pushing the boundaries of its potential. One promising area is the development of ultra-high-performance orthogneiss (UHPO), a specially engineered material that exhibits exceptional strength and fracture toughness. UHPO has the potential to revolutionize construction techniques, enabling the construction of lighter, more durable, and more sustainable structures.

Conclusion: Unlocking the Potential of Orthogneiss

Orthogneiss, a captivating rock formation with a rich geological history, offers a unique combination of strength, durability, and versatility. Its wide range of applications, from construction to landscaping, makes it a valuable material for architects, engineers, and landscapers alike. By understanding the properties and characteristics of orthogneiss, we can continue to harness its potential for innovative and sustainable projects.

Additional Tables: Enhancing Understanding

Table 1: Chemical Composition of Orthogneiss

| Oxide | Percentage Range (%) |

|---|---|

| Silica (SiO2) | 60-75 |

| Aluminum Oxide (Al2O3) | 10-15 |

| Potassium Oxide (K2O) | 5-10 |

| Sodium Oxide (Na2O) | 2-5 |

| Calcium Oxide (CaO) | 1-3 |

| Magnesium Oxide (MgO) | 0.5-2 |

| Iron Oxide (FeO) | 0.5-2 |

Table 2: Engineering Properties of Orthogneiss

| Property | Value Range |

|---|---|

| Compressive Strength (MPa) | 100-250 |

| Tensile Strength (MPa) | 5-15 |

| Shear Strength (MPa) | 10-20 |

| Young’s Modulus (GPa) | 50-80 |

| Poisson’s Ratio | 0.2-0.3 |

Table 3: Applications of Orthogneiss

| Application | Example |

|---|---|

| Construction | Foundations, walls, paving stones |

| Landscaping | Retaining walls, garden paths |

| Monuments | Statues, memorials, historical markers |

| Decorative | Countertops, fireplaces, outdoor sculptures |

| Engineering | Roadbeds, bridge piers, dams |

Table 4: Common Mistakes to Avoid with Orthogneiss

| Mistake | Consequence |

|---|---|

| Improper Handling | Breakage or damage |

| Exposure to Harsh Environments | Degradation or weakening |

| Insufficient Curing Time | Poor bonding and strength development |

| Overload | Structural failure |

| Inadequate Weatherproofing | Premature deterioration |