Unveiling the Enchanting World of Specularite

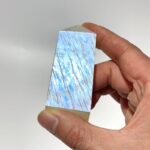

Specularite, a lustrous mineral renowned for its mirror-like surface, has captivated hearts and ignited imaginations for centuries. This captivating mineral is composed primarily of iron oxide and owes its distinctive sparkle to its platy crystal structure and high reflectance. Specularite’s captivating appearance has made it a sought-after ingredient in various industries, ranging from cosmetics and paints to industrial applications.

Specularite in Cosmetics: A Touch of Brilliant Shimmer

Specularite has become an indispensable ingredient in the cosmetic industry, where it adds a touch of shimmering brilliance to lipsticks, eye shadows, and nail polishes. Its unique optical properties allow it to reflect light in a multifaceted manner, creating an eye-catching, metallic effect that enhances the overall appearance of cosmetic products.

Pain Points:

-

Consumers desire cosmetics that enhance their natural features and create a radiant glow.

-

The beauty industry seeks ingredients that provide high-intensity shimmer without compromising product texture or performance.

-

Cosmetic formulators face challenges in incorporating specularite into formulations while maintaining product stability and avoiding settling.

Motivations:

-

Specularite’s high refractive index and platy structure enable intense shimmer and reflection, meeting consumer demand for glamorous makeup looks.

-

Its natural mineral composition appeals to consumers seeking eco-conscious and skin-friendly ingredients.

-

Cosmetic manufacturers recognize specularite’s ability to elevate product appeal and differentiate their offerings in a competitive market.

Specularite in Paints: A Symphony of Reflective Hues

The paint industry also embraces specularite’s unique properties, utilizing it to create high-performance paints with exceptional reflective qualities. Specularite-enhanced paints are particularly sought after for industrial applications, where they offer superior protection against corrosion and UV radiation, while also providing a sleek, metallic finish.

Pain Points:

-

Industrial coatings demand high corrosion and UV resistance to ensure durability in harsh environments.

-

Manufacturers seek cost-effective solutions that enhance product performance without compromising quality.

-

Paint formulators strive to achieve a balance between reflectivity and durability, ensuring a balance between aesthetics and protection.

Motivations:

-

Specularite’s inherent corrosion and UV resistance properties make it an ideal additive for protective coatings, extending asset lifespan and reducing maintenance costs.

-

Its platy structure enhances light scattering, resulting in high reflectivity and a metallic sheen, enhancing product aesthetics.

-

By incorporating specularite, paint manufacturers can differentiate their products and cater to specific industry requirements, such as automotive, marine, and industrial coatings.

Emerging Applications: Unlocking Specularite’s Potential

Beyond the well-established applications in cosmetics and paints, specularite has sparked the imagination of researchers and innovators, leading to the exploration of novel applications. Its unique optical properties and reflective nature inspire the development of cutting-edge technologies and products.

Specularite in Solar Cells: Harnessing Light for Energy Conversion

The solar industry looks to specularite as a promising material for enhancing solar cell efficiency. Its high reflectivity and low absorption of light make it an ideal candidate for use in light-trapping and anti-reflection coatings. By incorporating specularite, solar cells can capture more sunlight, leading to increased energy conversion and improved overall performance.

Specularite in 3D Printing: Sculpting with Reflective Precision

The advent of 3D printing has opened up new avenues for specularite applications. By incorporating specularite into 3D printing materials, it is possible to create objects with reflective surfaces and enhanced structural integrity. This opens up possibilities for creating intricate 3D printed objects with both functional and aesthetic appeal.

Common Mistakes to Avoid: Navigating Specularite Applications

While specularite offers immense potential, certain common mistakes can hinder the effective utilization of this remarkable mineral. Addressing these pitfalls is crucial for maximizing the benefits of specularite and ensuring successful product development.

-

Avoid excessive specularite concentration, as it can lead to diminished product performance and reduced durability.

-

Ensure proper dispersion of specularite particles to prevent agglomeration and ensure uniform shimmer or reflectivity.

-

Carefully select the appropriate specularite particle size based on the desired application to optimize optical effects and avoid settling issues.

-

Conduct thorough testing and evaluation to ensure stability and compatibility of specularite with other ingredients in the formulation.

By avoiding these common pitfalls, manufacturers and researchers can harness the full potential of specularite and develop innovative products that meet the evolving needs of consumers and industries alike.

Table 1: Specularite Properties and Applications

| Property | Value |

|---|---|

| Composition | Iron oxide (Fe2O3) |

| Crystal Structure | Platy |

| Color | Black |

| Luster | Metallic |

| Hardness | 5-6 on the Mohs scale |