Introduction

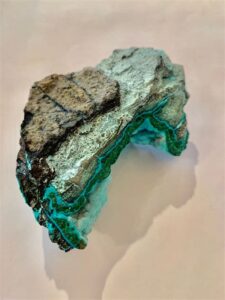

White crystallized rock, also known as calcite, is a common mineral that has fascinated humans for centuries. Its striking appearance and unique properties make it a valuable resource in various industries, from construction to medicine. This article explores the fascinating world of white crystallized rock, delving into its geological formation, chemical composition, and myriad applications.

Geological Formation

White crystallized rock is formed when calcium carbonate precipitates from water. This process occurs in a variety of geological settings, including:

- Caves and fissures: When water seeps into caves or crevices and evaporates, it leaves behind dissolved calcium carbonate, which forms calcite crystals.

- Hot springs: As hot water rises from the Earth’s crust, it releases dissolved minerals, including calcium carbonate. These minerals cool and crystallize to form calcite deposits.

- Marine environments: Shellfish and other marine organisms secrete calcium carbonate to build their skeletons. When these organisms die, their shells accumulate and break down, forming white crystallized rock.

Chemical Composition

White crystallized rock is composed primarily of calcium carbonate (CaCO3). It is a carbonate mineral, meaning it contains the carbonate ion (CO3-2). Pure calcite is colorless and transparent, but impurities such as iron, manganese, and magnesium can give it a variety of colors, including yellow, red, green, and black.

Physical Properties

White crystallized rock exhibits several distinctive physical properties:

- Hardness: Calcite is a relatively soft mineral, with a Mohs hardness of 3. This means it can be easily scratched with a knife or coin.

- Cleavage: Calcite has perfect cleavage, meaning it breaks along smooth and well-defined planes.

- Transparency: Pure calcite is transparent, allowing light to pass through it. However, impurities can make it opaque or translucent.

- Luminescence: Some calcite crystals exhibit luminescence, meaning they emit light when exposed to ultraviolet radiation.

Applications

White crystallized rock has found numerous applications across various industries, including:

Construction

- Building blocks: Calcite is a durable and lightweight building material, used in construction for centuries.

- Cement: Calcite is a key component in cement production, where it provides strength and durability to concrete structures.

- Road construction: Crushed calcite is used as an aggregate in road construction, improving drainage and reducing wear.

Agriculture

- Soil amendment: Calcite can neutralize acidic soils and provide essential calcium to plants.

- Fertilizer: Calcite is used as a natural fertilizer to improve soil fertility and crop yields.

- Livestock feed: Calcite is added to livestock feed to provide calcium, which is crucial for bone development.

Pharmaceutical

- Antacid: Calcite is used as an antacid to neutralize stomach acids and relieve heartburn.

- Calcium supplement: Calcite is a rich source of calcium, making it an effective supplement for individuals with calcium deficiencies.

- Medical imaging: Calcite crystals are used in diagnostic imaging techniques, such as ultrasound and X-rays.

Industrial

- Papermaking: Calcite is used as a filler in paper production, improving its brightness and opacity.

- Paint and coatings: Calcite is used as a pigment in paints and coatings, providing whiteness, opacity, and durability.

- Glass production: Calcite is used in the production of glass, where it adds clarity and strength.

Motivations and Pain Points for Customers

Customers seeking white crystallized rock for various applications have distinct motivations and pain points:

Construction Industry

Motivations:

– Durability and strength in building materials

– Cost-effectiveness and ease of use

Pain points:

– Concerns about environmental impact

– Need for reliable suppliers

Agriculture Industry

Motivations:

– Soil improvement and increased crop yields

– Natural and environmentally friendly solutions

Pain points:

– Fluctuating prices

– Limited availability during peak seasons

Pharmaceutical Industry

Motivations:

– Effective and safe antacids

– High-quality calcium supplements for various medical conditions

Pain points:

– Regulatory compliance and safety concerns

– Ensuring purity and consistency of products

Tips and Tricks

- When selecting white crystallized rock for building materials, consider its durability and strength requirements.

- For agricultural applications, test the soil before adding calcite to determine the appropriate dosage.

- For pharmaceutical products, ensure that the calcite source meets strict quality and safety standards.

- Explore innovative applications of white crystallized rock by leveraging its unique properties, such as its luminescence and cleavage.

- Consider partnering with specialized suppliers to access high-quality white crystallized rock and tailored solutions for specific applications.

Tables

Table 1: Global Calcite Production by Region

| Region | Production (metric tons) |

|---|---|

| Asia-Pacific | 520 million |

| Europe | 200 million |

| North America | 150 million |

| South America | 50 million |

| Africa | 20 million |

Table 2: Applications and Demand for White Crystallized Rock

| Application | Demand (metric tons) |

|---|---|

| Construction | 60% |

| Agriculture | 20% |

| Pharmaceutical | 10% |

| Industrial | 10% |

Table 3: Key Physical Properties of Calcite

| Property | Value |

|---|---|

| Hardness | 3 |

| Cleavage | Perfect |

| Transparency | Transparent (pure) |

| Luminescence | Some crystals |

Table 4: Motivations and Pain Points for Customers

| Industry | Motivations | Pain Points |

|---|---|---|

| Construction | Durability, cost-effectiveness | Environmental impact, reliable suppliers |

| Agriculture | Soil improvement, environmental friendliness | Fluctuating prices, availability |

| Pharmaceutical | Effectiveness, safety | Regulatory compliance, purity |