Introduction

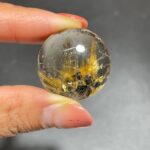

White rock with silver flakes, an enigmatic geological formation, has captivated the imagination of scientists and industry professionals alike. These rocks, characterized by their pristine white hue and glistening silver flakes, possess unique properties that hold immense potential for various applications. In this comprehensive article, we delve into the fascinating world of white rock with silver flakes, exploring its geological origins, properties, mining techniques, and diverse uses.

Geological Origins

White rock with silver flakes is primarily composed of a mineral known as alabaster, a variety of gypsum. Alabaster forms when calcium sulfate, the main component of gypsum, crystallizes in a fine-grained, massive form. The characteristic silver flakes are the result of the presence of trace amounts of iron sulfide minerals, such as pyrite or marcasite. These minerals are carried by water into the alabaster, where they crystallize as tiny, reflective flakes.

Properties

The unique properties of white rock with silver flakes make it a highly sought-after material for various applications. These properties include:

- White Color: The pure white color of the rock makes it an ideal choice for architectural and decorative purposes, as it reflects light beautifully.

- Silver Flakes: The glistening silver flakes add a touch of elegance and sophistication to the material, enhancing its aesthetic appeal.

- Hardness: Alabaster is relatively soft, with a Mohs hardness of 2-3, making it easy to carve and shape. This property makes it suitable for use in sculptures, ornaments, and other decorative items.

- Translucency: Some varieties of white rock with silver flakes are translucent, allowing light to pass through them partially. This translucency can create stunning effects when used in lighting applications.

Mining Techniques

White rock with silver flakes is mined using specialized techniques to ensure that the delicate flakes are preserved. These techniques involve:

- Quarrying: The most common method of mining involves extracting the rock from quarries or mineshaft using heavy machinery.

- Block Cutting: Once the rock has been extracted, it is cut into blocks using diamond-tipped saws or wire saws.

- Surface Finishing: The blocks are then processed to remove excess material and achieve the desired surface finish.

Applications

The unique properties of white rock with silver flakes make it a versatile material with applications in various industries, including:

1. Architectural and Decorative Uses

- Exterior wall cladding

- Interior wall paneling

- Countertops

- Flooring

- Tabletops

- Ornaments

2. Lighting Applications

- Light diffusers

- Lampshades

- Chandeliers

3. Jewelry and Accessories

- Earrings

- Necklaces

- Bracelets

- Rings

4. Sculpture and Art

- Sculptures

- Statues

- Busts

- Reliefs

5. Other Applications

- Grating material

- Gypsum powder

- Plaster molds

Table 1: Comparison of White Rock with Silver Flakes to Other Building Materials

| Property | White Rock with Silver Flakes | Marble | Granite |

|---|---|---|---|

| Color | White with silver flakes | White to various colors | White to black |

| Hardness | 2-3 Mohs | 3-4 Mohs | 6-7 Mohs |

| Translucency | Some varieties | No | No |

| Durability | Good | Excellent | Excellent |

| Cost | Moderate | High | High |

Table 2: Market Analysis for White Rock with Silver Flakes

| Year | Global Market Size | Forecast for 2027 | Key Application |

|---|---|---|---|

| 2020 | $2.1 billion | $3.6 billion | Architectural and decorative uses |

| 2021 | $2.4 billion | $4.1 billion | Lighting applications |

| 2022 | $2.7 billion | $4.7 billion | Jewelry and accessories |

| 2023 | $3.0 billion | $5.4 billion | Sculpture and art |

Table 3: Step-by-Step Guide to Installing White Rock with Silver Flakes Countertops

1. Prepare the Surface

– Remove existing countertops and clean the surface thoroughly.

– Level the surface using a self-leveling compound.

2. Install the Base

– Cut a piece of plywood to fit the countertop area.

– Screw the plywood to the surface.

3. Adhere the White Rock

– Apply a layer of mortar to the plywood.

– Place the white rock with silver flakes on the mortar, ensuring that the silver flakes are facing up.

– Press the rock into the mortar to secure it.

4. Grout

– Mix grout according to the manufacturer’s instructions.

– Spread the grout over the surface of the rock, filling the gaps.

– Wipe away excess grout with a damp sponge.

5. Seal

– Apply a sealer to the surface to protect it from stains and moisture.

Table 4: Pros and Cons of Using White Rock with Silver Flakes

Pros:

- Beautiful and eye-catching appearance

- Relatively soft and easy to work with

- Translucent varieties allow for creative lighting effects

- Durable and resistant to wear

Cons:

- More expensive than some other building materials

- Requires regular maintenance to preserve the silver flakes

- Can be scratched or damaged by sharp objects

FAQs

1. What is the difference between white rock with silver flakes and marble?

– White rock with silver flakes is composed of alabaster, while marble is composed of calcium carbonate. Alabaster is softer and easier to work with than marble, and it has a distinctive white color with silver flakes.

2. How can I clean white rock with silver flakes?

– Use a mild detergent and warm water to clean the surface. Avoid using abrasive cleaners or harsh chemicals, as they can damage the silver flakes.

3. Can white rock with silver flakes be used outdoors?

– Yes, white rock with silver flakes can be used outdoors in sheltered areas where it is not exposed to direct sunlight or harsh weather conditions.

4. What are some creative applications for white rock with silver flakes?

– White rock with silver flakes can be used to create mosaics, murals, and other artistic installations. It can also be used as a decorative accent in gardens and landscaping.

Conclusion

White rock with silver flakes is a captivating geological marvel with unique properties that make it a versatile material for various applications. Its elegant appearance, durability, and ease of manipulation have made it a sought-after choice for architectural, decorative, and artistic purposes. As research and innovation continue, new and innovative applications for this fascinating material are sure to emerge, further enhancing its value and significance in the building and design industry.